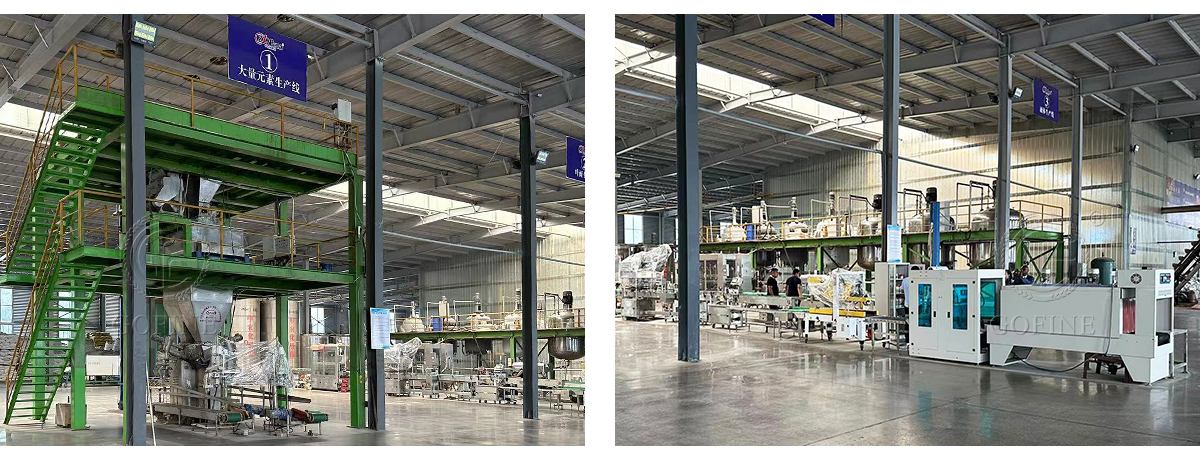

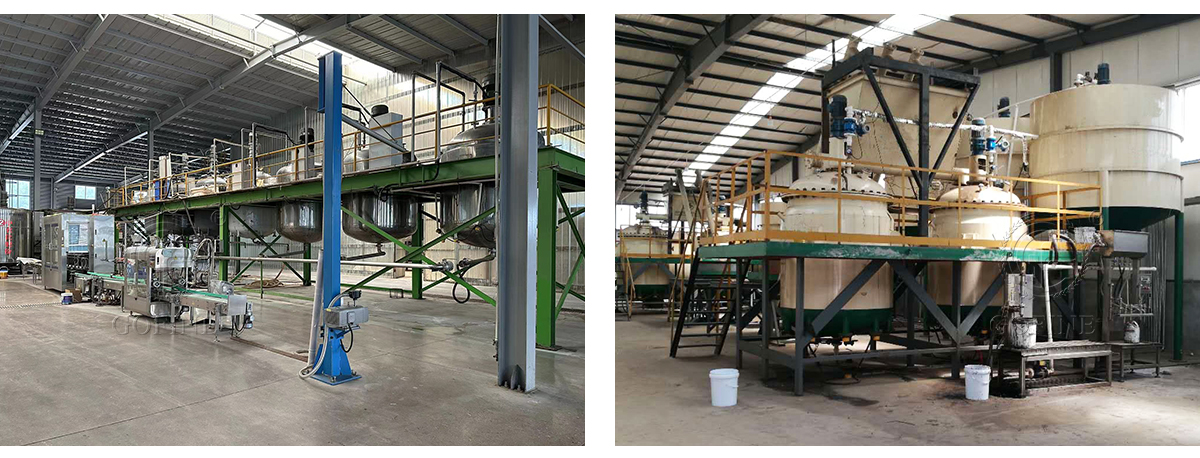

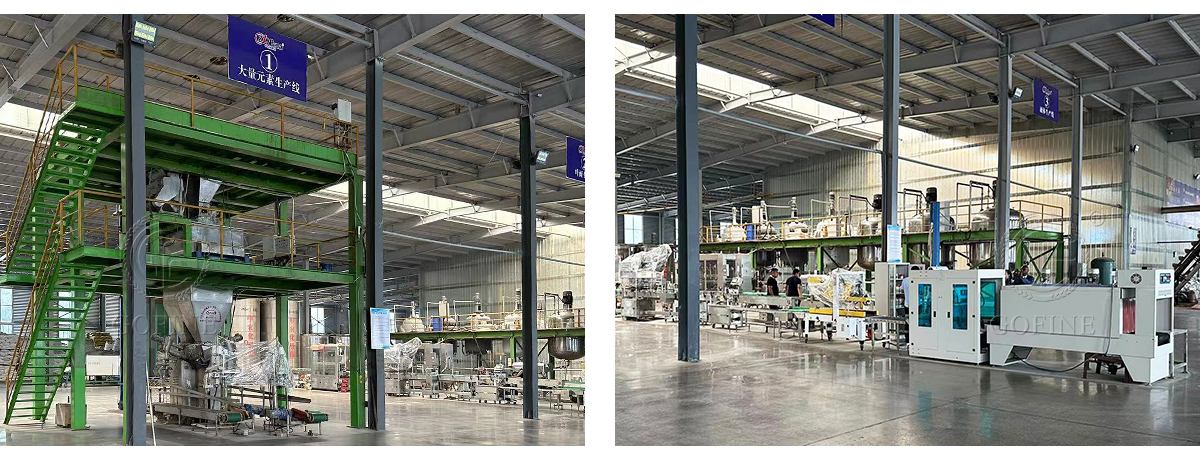

The Liquid Fertilizer Production Line is a comprehensive solution for producing high-quality foliar fertilizers, water-soluble fertilizers, and drip irrigation fertilizers. Designed to meet the demanding needs of fertilizer production, this line offers rapid packaging, precise filling, and minimal failure rates, making it ideal for fertilizer processing plants, agrochemical industries, and chemical or compound fertilizer manufacturers. The system is engineered to operate efficiently in various complex environments, providing unmatched reliability and performance.

The entire production line is designed with anti-corrosion materials, ensuring durability and easy maintenance. With 304 stainless steel or plastic used for all parts in contact with materials, the line maintains hygiene and reliability throughout the entire manufacturing process. Whether for bulk production or small batches, the liquid fertilizer production line is engineered to enhance operational efficiency and product consistency.

Key Features and Benefits

High-Speed Packaging: The liquid fertilizer production line is equipped with advanced technology to handle fast packaging speeds without compromising on accuracy. This ensures high throughput while maintaining precision and low failure rates, which are critical for consistent product quality.

Durable and Corrosion-Resistant Design: All components in direct contact with materials are made from 304 stainless steel or high-quality plastic, which ensures long-term durability and corrosion resistance. This is essential for preventing material degradation and maintaining the quality of the fertilizers produced.

Versatility Across Fertilizer Types: This production line is suitable for a wide range of liquid fertilizers, including foliar fertilizers, water-soluble fertilizers, and drip irrigation fertilizers. Its flexible design makes it ideal for customized fertilizer formulations, ensuring that it can meet the varying needs of the fertilizer industry.

Easy Cleaning and Maintenance: The anti-corrosion design and modular structure of the liquid fertilizer production line make it simple to clean and maintain, reducing downtime and improving overall efficiency. The ease of maintenance helps ensure that the system operates at optimal performance levels.

Precision and Efficiency: The system delivers high levels of precision in the packaging and filling process, ensuring that each batch of fertilizer is consistently produced to meet quality standards. Its efficient operation minimizes waste and enhances production consistency, optimizing the overall output of your fertilizer production process.

Wide Industry Application: This production line is widely used in fertilizer processing plants, agrochemical companies, and other industries where liquid fertilizers are required. Whether used for agricultural, horticultural, or landscaping applications, this line supports the growing demand for high-quality, efficient liquid fertilizer solutions.

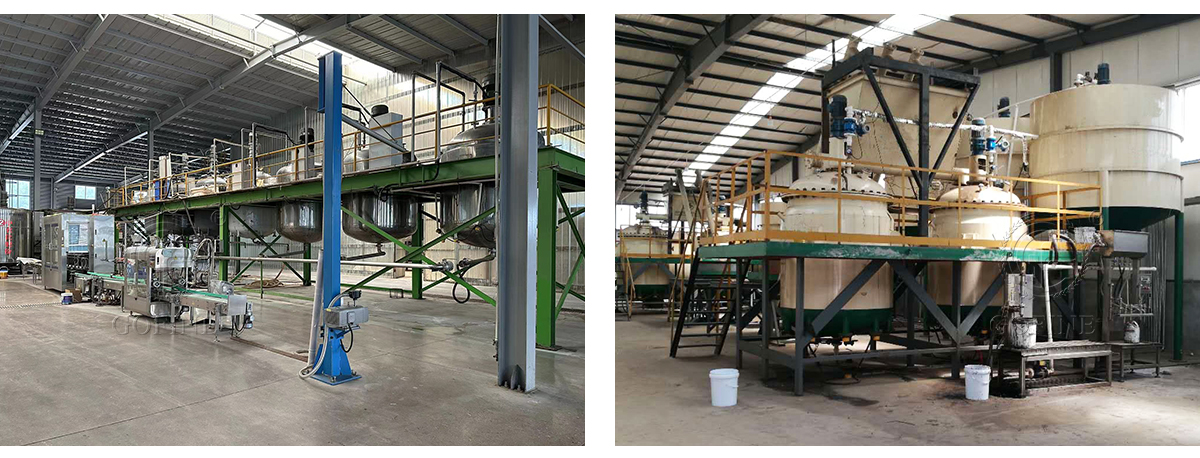

Working Principle

The Liquid Fertilizer Production Line operates with a highly efficient process that involves the following steps:

Raw Material Preparation: The raw materials, including water-soluble and foliar fertilizer components, are mixed and prepared according to the specific formulation needed for each product type.

Filling and Packaging: The liquid fertilizer is then transferred to precise filling machines, which handle the packaging process with high accuracy. The system ensures that the fertilizer is dispensed into bottles, bags, or other containers at optimal speeds, maintaining consistency throughout the process.

Quality Control and Final Packaging: After the filling process, each batch undergoes quality checks to ensure it meets the desired standards. Once approved, the final products are sealed and prepared for distribution.

Advantages of the Liquid Fertilizer Production Line

Increased Productivity: The line’s high packaging speed and precision filling process significantly improve overall productivity, reducing labor costs and increasing output.

Long-Lasting Durability: With the use of 304 stainless steel and high-quality plastic, the production line components are designed to last, even under harsh working conditions, ensuring reliable performance over time.

Low Maintenance Costs: The design of the system minimizes maintenance requirements, making it a cost-effective choice for manufacturers looking to reduce operational downtime and maintenance costs.

Customization and Flexibility: The liquid fertilizer production line is highly customizable, making it suitable for different fertilizer types and production scales. Whether you need to produce high-concentration foliar fertilizers or specialized drip irrigation fertilizers, this system can be adapted to suit your specific needs.

Applications

This liquid fertilizer production line is essential for various industries that rely on liquid fertilizers for agricultural and horticultural applications, including:

Agrochemical Industry: Manufacturing a range of liquid plant nutrients and pesticides.

Agriculture: Producing foliar fertilizers and water-soluble fertilizers that support plant growth and improve crop yields.

Horticulture: Creating custom liquid fertilizer blends tailored to specific plant species and growing conditions.

Landscape and Turf Care: Developing efficient drip irrigation fertilizers that ensure consistent nutrient delivery.

Why Choose This Liquid Fertilizer Production Line?

If you are looking for an efficient, durable, and highly customizable liquid fertilizer production system, this line is your ideal solution. With precision packaging, low maintenance costs, and corrosion-resistant construction, it meets the needs of modern fertilizer manufacturers and agrochemical companies. Whether you are producing foliar fertilizers, drip irrigation solutions, or water-soluble fertilizers, this line ensures high efficiency, minimal downtime, and superior product quality.

Choose the Liquid Fertilizer Production Line for an advanced, reliable, and cost-effective solution to enhance your fertilizer manufacturing processes. It is the key to improving your productivity, product quality, and overall business performance.

Application of Liquid Fertilizer Production Line