The fully automatic packaging production line is an efficient and highly automated production line used to package various products, such as food, cosmetics, medicines, chemicals, etc. The production line integrates a variety of equipment and processes, and can realize the full process automation from product metering, packaging, sealing to finished product delivery.

Product Features

Efficient automation: Realize the automation of the entire process from product loading to finished product output, greatly improve production efficiency and reduce labor costs.

High packaging accuracy: Adopt advanced measurement and control systems to ensure that packaging weight, size, appearance and other parameters are accurate and reliable.

Strong adaptability: According to the packaging needs of different products, equipment parameters can be flexibly adjusted and molds can be replaced to adapt to a variety of packaging forms and specifications.

Sanitary and safe: Made of materials that meet food hygiene standards, easy to clean and maintain, ensuring product hygiene and safety.

Stable and reliable: Adopt high-quality components and advanced control systems, stable and reliable operation, low failure rate.

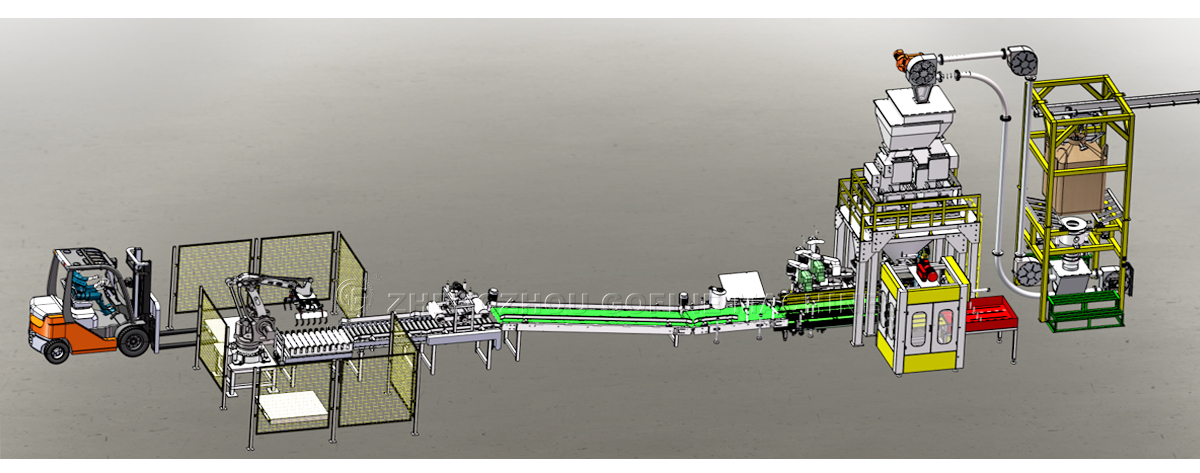

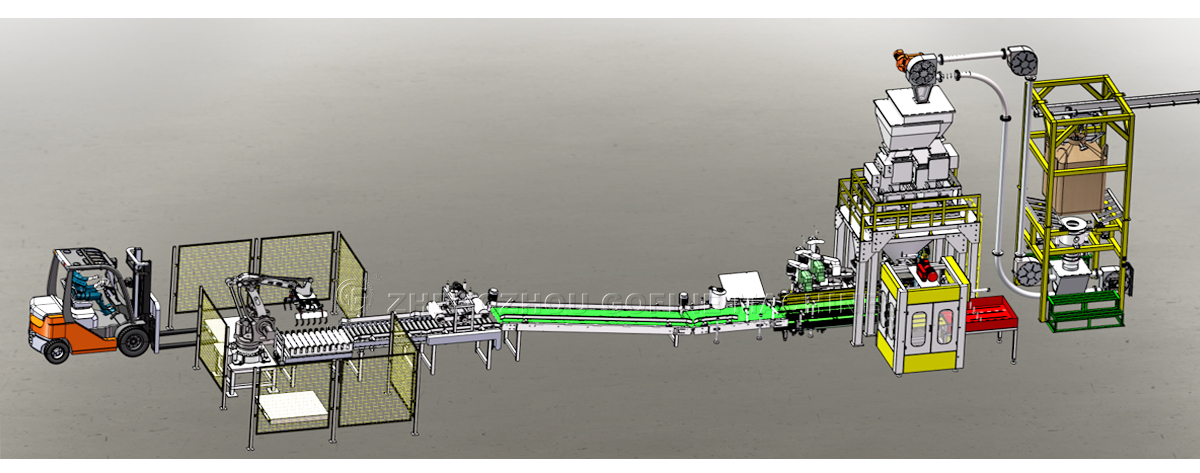

Automatic Packaging Production Line Process Flow

The entire process of an automatic packaging production line from bagging system to palletizing usually includes the following main steps and equipment:

1. Bagging system

Feeding: The product is transported from the front end of the production line to the bagging system.

Packing bag supply: The automatic bagging system provides bags, usually pre-made bags.

Opening the bag: The machine opens the bag and prepares to receive the product.

2. Measuring and filling

Measuring device: The product passes through the metering device to ensure that the amount of product in each bag reaches the preset standard.

Filling: The product is filled into the pre-opened bag.

3. Sealing and bottom sealing

Sealing: The product in the bag passes through the sealing mechanism for sealing operation to ensure that the product does not leak.

Bottom sealing: Some systems may also include the step of sealing the bottom of the bag.

4. Marking and quality inspection

Marking: After the product is packaged, it may be printed or labeled, including information such as production date and batch number.

Quality inspection: The system may perform quality inspections to ensure that the packaging is complete and the product meets the standards.

5. Conveying and palletizing

Conveying: The packaged products are transported to the palletizing area by conveying equipment.

Palletizing: Robots or automated equipment palletize the packaged products according to set rules and stack them into neat cargo stacks.

Automatic packaging production lines for the entire process are usually equipped with automatic control systems to monitor and control the entire packaging process to ensure product packaging quality and production efficiency. This fully automated packaging production line is suitable for industries such as food, cosmetics, and pharmaceuticals, and can greatly improve production efficiency and packaging consistency.

Application of Automatic Packaging Production Line

Agricultural products: packaging of agricultural products such as seeds, fertilizers, pesticides, etc.

Chemical products: packaging of powdered or granular chemical raw materials or products, such as pigments, plastic particles, etc.

Food: including various foods such as granular, powdered, liquid, such as rice, flour, sugar, coffee, tea, nuts, biscuits, puffed food, beverages, etc.

Cosmetics: packaging of various cosmetic products, such as foundation, lipstick, eye shadow, facial mask, etc.

Daily necessities: packaging of daily household items such as washing powder, shampoo, shower gel, detergent, etc.

The scope of application of automatic packaging machines is very wide. As long as the materials meet the requirements of the packaging machine (such as shape, size, weight, etc.), automatic packaging operations can be performed. This efficient and precise automatic packaging method can improve production efficiency, save costs, and ensure the consistency and stability of packaging quality.

Detail pictures