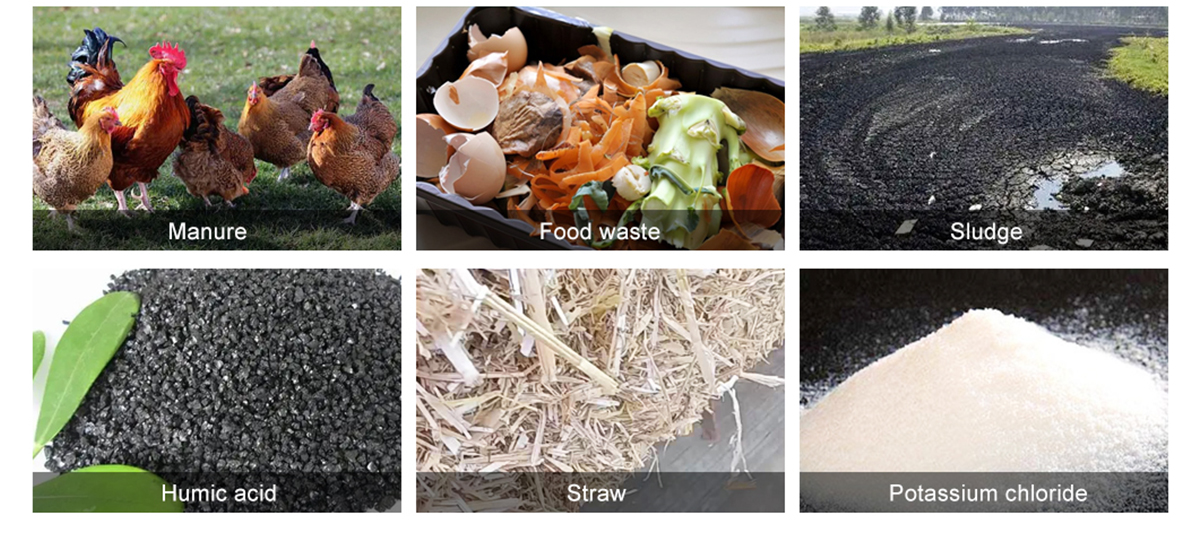

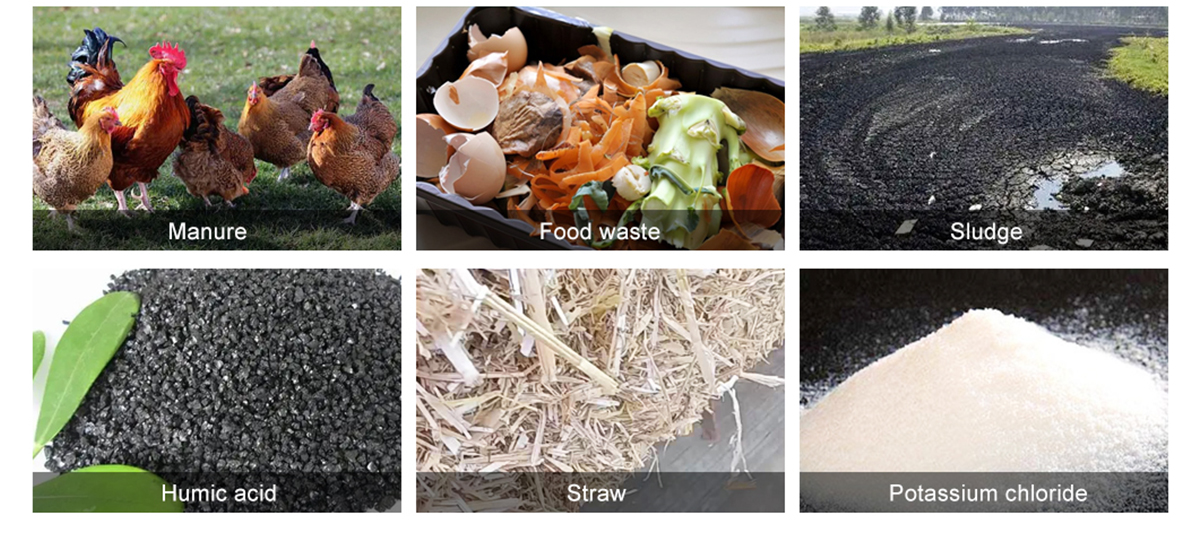

There are many raw materials for organic fertilizer, It can be divided into the following categories:

1. Agricultural waste: such as straw, soybean meal, cotton meal, mushroom residue, biogas residue, fungus residue, lignin residue, etc.

2. Livestock and poultry manure: such as chicken manure, cattle, sheep and horse manure, rabbit manure;

3. Industrial wastes: such as distiller's grains, vinegar grains, cassava residues, sugar residues, furfural residues, etc.;

4. Domestic waste: such as kitchen waste, etc.;

5. Urban sludge: such as river sludge, sewage sludge, etc. China's organic fertilizer raw materials classification: mushroom residue, kelp residue, phosphorus citric acid residue, cassava residue, sugar aldehyde residue, amino acid humic acid, oil residue, shell powder, etc., concurrently, peanut shell powder, etc.

6. The development and utilization of biogas slurry and residue is one of the important contents of biogas promotion. According to many years of experiments, the use of biogas slurry and residue has many functions such as fertilizer fields, improving soil, preventing and controlling diseases and insects, and increasing yields.