| Model | PYJ 800-2 | PYJ 1000-2 | PYJ 1200-2 | PYJ 1200-3 | PYJ 1500-2 | PYJ 1500-3 |

| Yield(t/h) | 2.2-3.5 | 3.5-5 | 4-7 | 6-9 | 5-8 | 7-10 |

| Ball forming rate | ≥ 95% | ≥ 95% | ≥ 95% | ≥ 95% | ≥ 95% | ≥ 95% |

| Particle temperature | <30 Celsius | <30 Celsius | <30 Celsius | <30 Celsius | <30 Celsius | <30 Celsius |

| Power(kw) | 4x2 | 5.5x2 | 7.5x2 | 7.5x3 | 11x2 | 11x3 |

| Spindle diameter(mm) | 800mm | 1000mm | 1200mm | 1200mm | 1500mm | 1500mm |

| Applicability | Fertilizer, feed, and other particles etc. |

Technical Specifications

Ball Forming Rate: ≥95%

Production Capacity: High output, capable of handling large quantities of materials

Energy Consumption: Low, ensuring efficient use of power

Maintenance: Easy to maintain with simple parts and clear instructions

Materials Handled: Suitable for a wide range of organic materials, including composted manure, plant residues, and other organic waste

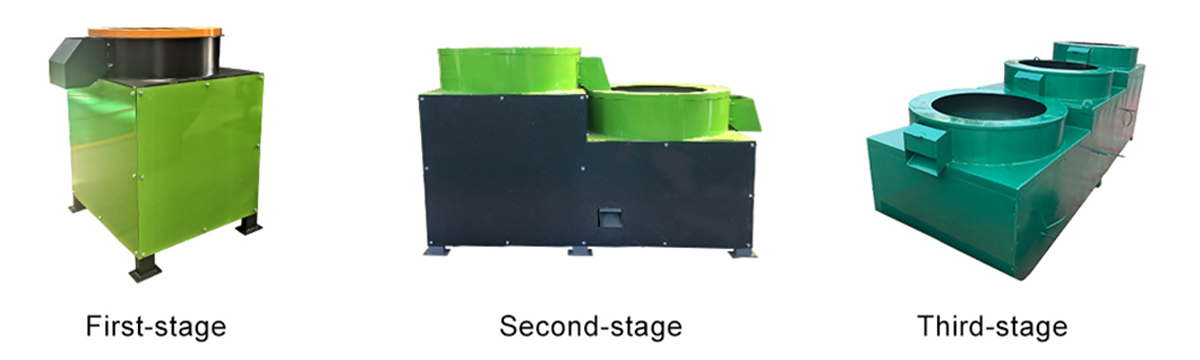

Disc Arrangement: Two or more round polishing discs arranged to ensure uniform polishing and shaping of the granules.

Application of round polishing machine in production line

The Organic Fertilizer Round Shaping Machine is widely used in various industries, including:

Organic Fertilizer Production: Ideal for shaping organic fertilizer pellets into uniform, high-density granules suitable for agricultural use. This ensures better nutrient release and efficient soil application.

Compost Pellets: Converts composted materials into round pellets for better handling, storage, and ease of application, enhancing the fertilizing effect on crops.

Waste Management: Used to process organic waste into valuable, uniform fertilizer pellets, supporting sustainable waste management practices and contributing to environmental protection.

How the Organic Fertilizer Round Shaping Machine Works

The process begins by feeding the granulated material into the shaping machine, where the material is guided into a series of round polishing discs. These discs rotate, polishing the granules repeatedly until they are shaped into smooth, uniform spheres. The final product is discharged through the outlet, with minimal fines left over.

This machine ensures that the pellets are consistent in size and shape, which is crucial for uniform fertilizer application and efficient use. The high ball forming rate ensures that the pellets are ideal for storage, transport, and eventual application, reducing dust and material waste.

Why Choose the Organic Fertilizer Round Shaping Machine?

If you're looking to streamline your fertilizer production process, the Organic Fertilizer Round Shaping Machine offers an efficient, cost-effective solution. With its ability to work with multiple granulators, low maintenance needs, and high productivity, it is the ideal choice for businesses aiming to produce consistent, high-quality organic fertilizer pellets. The machine’s low energy consumption, durability, and ease of operation ensure that your production line will run smoothly and efficiently, ultimately leading to higher output and greater profitability.

By enhancing the consistency and quality of your fertilizer granules, this machine helps ensure better crop yields, more efficient soil fertilization, and a more sustainable approach to agricultural practices.