Scope of application:

Used for automatic packaging of powdery materials in flour, starch, feed and food, chemical, light industry, building materials and other industries.

Features:

High precision: high-precision weighing controller is selected, which has good reliability.

Good integrity: small footprint, flexible and convenient installation.

Adjustable speed: the feeding method of powder equipment is spiral feeding, fast feeding and slow feeding are realized by the controller, and the feeding speed can be adjusted arbitrarily.

Environmentally-friendly operation: The internal circulation system is closed to effectively prevent dust from flying, improve the working environment, and protect the health of employees.

Reasonable structure: compact structure, small size, and can be made into a fixed body according to user requirements.

Host material: The parts contacting the material are made of stainless steel to ensure the overall durability of the equipment.

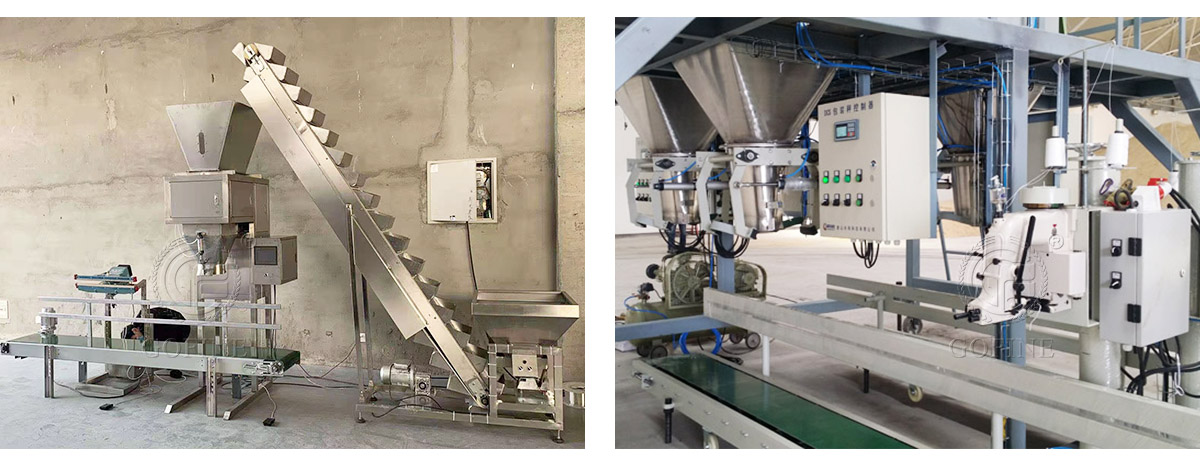

The unit is mainly composed of four parts: automatic weighing and packaging machine, conveying device, sewing machine, and storage bin. It has the characteristics of reasonable structure, beautiful appearance, convenient operation and accurate weighing.