The dust-free cage mill crusher is an efficient crushing equipment, mainly used to process hard materials with a moisture content of less than 40%. Its design can effectively improve the dust generated during the crushing process, protect the health of workers, and improve work efficiency. The cage crusher machine adopts a double-layer cage bar crushing structure inside, which is widely used in the crushing of chemical raw materials, phosphate fertilizers, DAP, grains, dried fruits, and other materials. It has strong adaptability to materials, is not easy to clog, and has smooth cutting.

Features of Dust-free Cage Crushing Equipment

The equipment is equipped with a cyclone dust removal device, which can effectively control the generation of dust during the entire crushing process, ensuring the cleanliness of the working environment and the health of workers.

The dust-free cage crusher adopts the impact-crushing principle. The inner and outer groups of cage bars rotate at high speed in opposite directions. The material is crushed by the impact of the cage bars, and the crushing efficiency is high.

The equipment structure design is simple, easy to clean and maintain, and reduces the complexity of operation.

Good sealing performance: The machine has good sealing performance, which can effectively prevent material leakage and keep the working environment clean.

The equipment runs smoothly during operation, reduces vibration and noise, and provides a comfortable working environment.

The dust-free cage pulverizer is suitable for crushing various single fertilizers, especially materials with higher hardness, and can process raw materials with a moisture content of less than 40%.

These characteristics make the dust-free cage-crushing processing equipment an indispensable piece of equipment in the production line of organic fertilizers and compound fertilizers.

Working Process of Dust-free Cage Crushing Equipment

The dust-free cage mill equipment forms a strong impact force through the high-speed rotation of the inner and outer cage bars, so that the material is quickly crushed during the rotation process. The material is subjected to multiple impacts and shearing inside the equipment to ensure the uniformity and fineness of the crushing.

High-performance cage crusher is suitable for crushing a variety of materials. Mainly including:

1. Food

Grains and dried fruits: such as wheat, corn, rice, nuts, dried fruits, etc.

Spices: such as chili powder, pepper, herbs, etc.

Sugar and salt: such as sugar, table salt, etc.

2. Chemicals

Compound fertilizer raw materials: urea, ammonium sulfate, phosphoric acid, superphosphate, potassium chloride, etc.

Resins and plastics: polymers, synthetic resins, etc.

3. Feed

Feed raw materials: grains, soybean meal, mineral additives, etc.

4. Environmental protection

Recyclable materials: waste plastics, paper, etc.

Solid waste treatment: sludge and other solid waste.

5. Others

Ore: certain non-metallic ores.

Organic fertilizer: compost, animal manure fertilizer, etc.

Technical Parameters of Cage Crushing Equipment

| Model | Feed port size (mm) | Power (kW) | Production capacity (t/h) | Overall dimensions (mm) |

| GFLSJ-600 | 380*320 | 11*2 | 4-6 | 1500*1500*1500 |

GFLSJ-800

| 380*250 | 15*2 | 6-10 | 1500*1400*1500 |

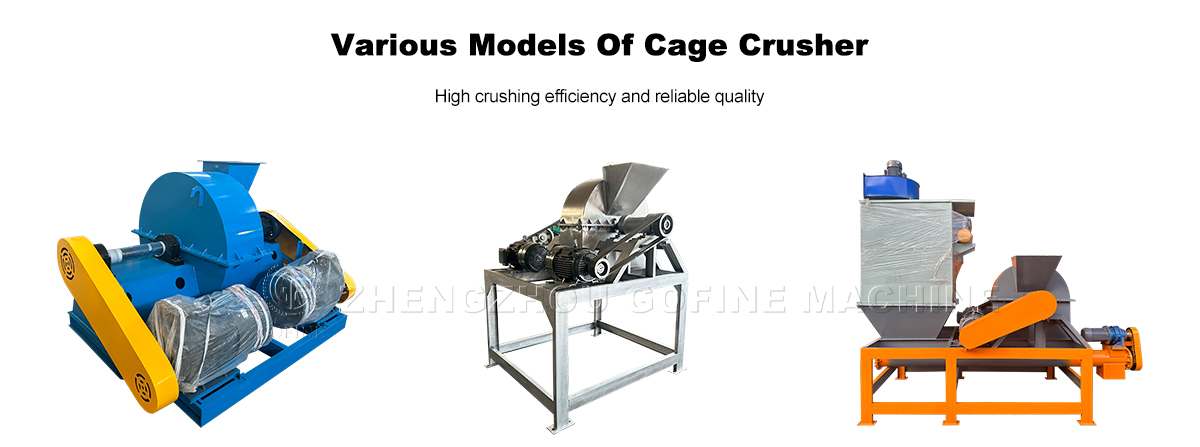

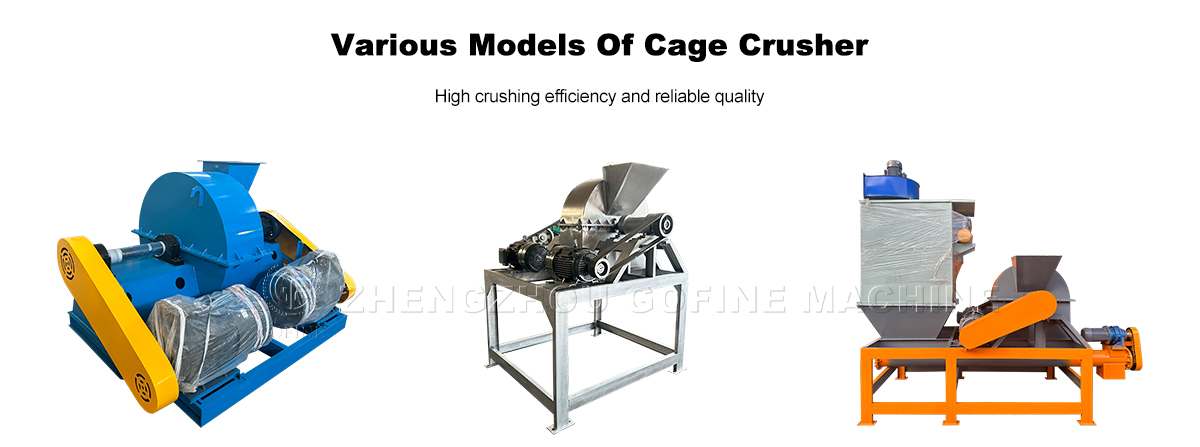

In addition to dust-free cage crushers, we also offer various models of stainless steel cage crushers and carbon steel cage crushers to meet your needs in crushing efficiency, material requirements and hygiene standards.

Our services include:

Customized solutions

24-hour professional online consultation

Installation and commissioning

Operation training services

After-sales service

Accessories supply

We are committed to providing customers with high-quality products and all-round support to help you improve production efficiency and product quality.

If you want to know more about fertilizer equipment, please feel free to contact me!