In industrial production, limestone, as an important raw material, is widely used in building materials, chemical industry, metallurgy and other fields. In order to process large pieces of limestone into a ,powder that meets production requirements, efficient limestone processing equipment is indispensable. Cage mill, as a classic industrial mill, occupies an important position in the field of limestone grinding with its unique structure and excellent performance.

Ⅰ. Cage mill crusher: simple structure, high crushing efficiency

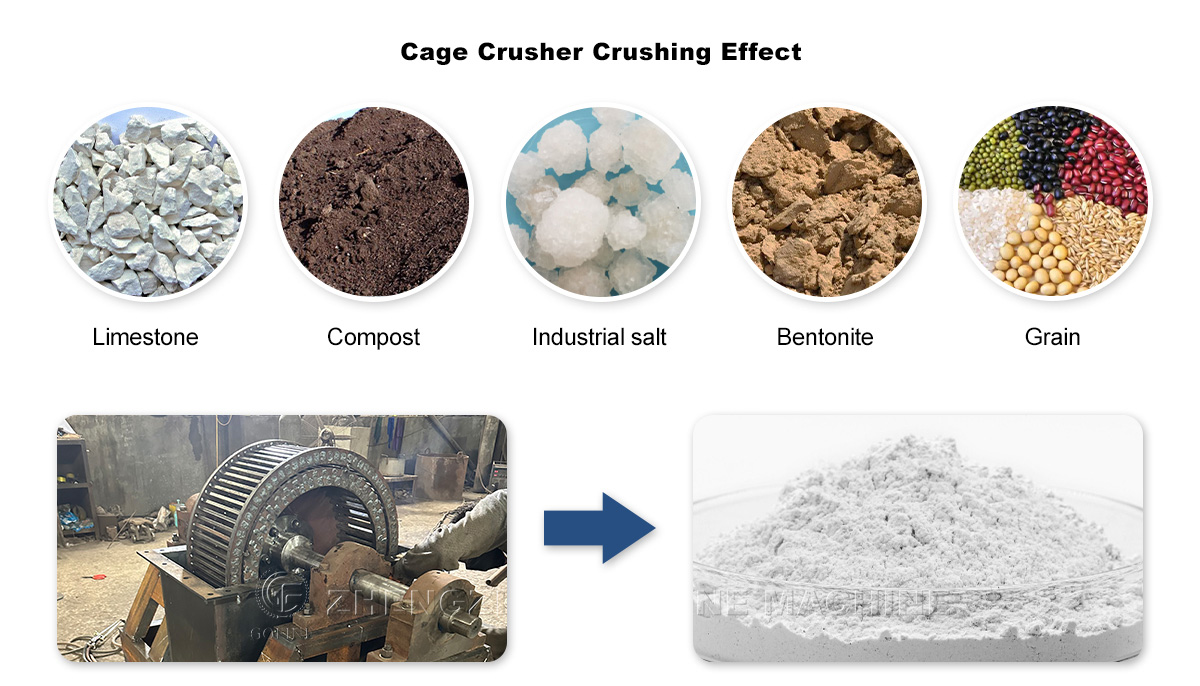

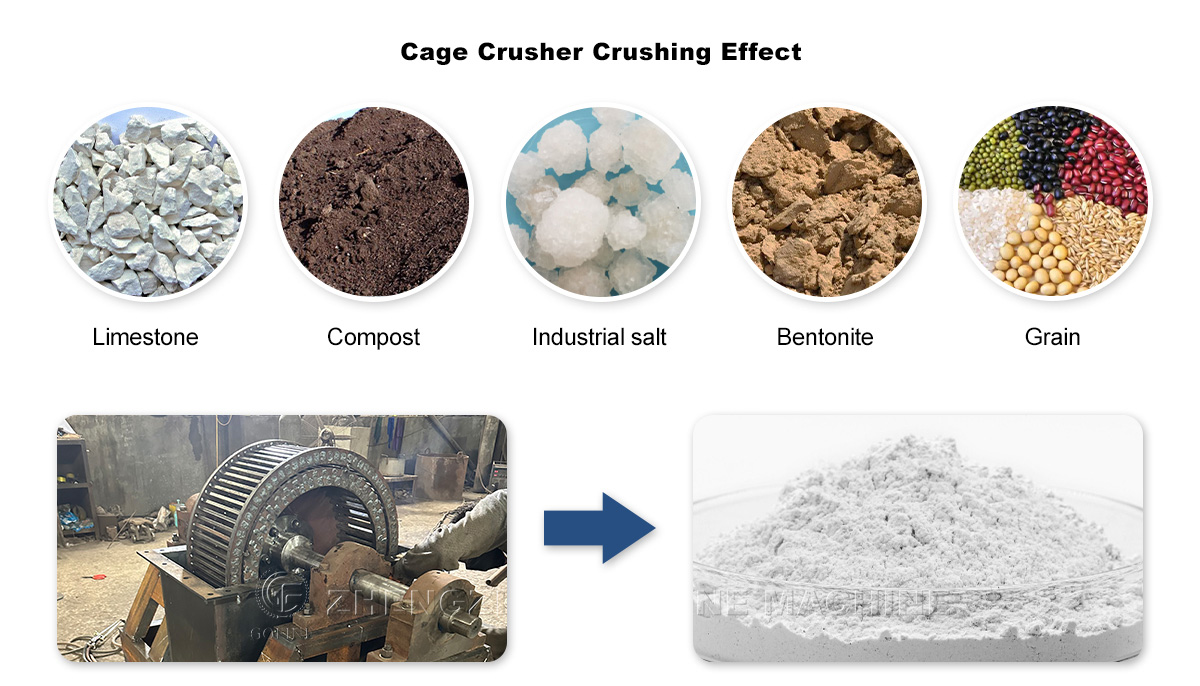

As the name implies, the core component of a cage grinder is a high-speed rotating cage rotor. The rotor is composed of multiple concentric steel bars, shaped like a birdcage, hence the name "cage". When working, the material enters the crushing chamber from the feed port. Driven by the high-speed rotating cage rotor, the material and the steel bars, and the material and the material collide, rub and shear violently, thus achieving crushing.

The cage crusher has a simple structure, is easy to maintain, has high crushing efficiency and low energy consumption, and is particularly suitable for crushing medium and low-hardness materials, such as limestone, gypsum, coal gangue, etc.

Ⅱ. Cage crushing machine: widely used, helping the development of multiple industries

Cage limestone crusher is widely used in multiple industries due to its excellent performance:

Building materials industry: used for crushing limestone, gypsum, and other materials, producing cement, lime, and other building materials.

Chemical industry: used for crushing phosphate ore, pyrite, and other materials, producing fertilizers, sulfuric acid, and other chemical products.

Metallurgical industry: used for crushing limestone, dolomite, and other materials as flux for iron and steel making.

Environmental protection industry: used for crushing waste slag, tailings and other materials to achieve resource utilization.

Ⅲ. Cage crushing equipment: clear working process and easy operation

The working process of a cage crusher is mainly divided into the following steps:

Feeding: The material enters the crushing chamber evenly through the feed port.

Crushing: The high-speed rotating cage rotor drives the material to move. The material is thrown around under the action of centrifugal force, collides, rubs, and shears with the steel rod and the inner wall of the crushing chamber, thereby achieving crushing.

Grading: The crushed material is discharged through the gap between the rotor and the shell, the material with qualified fineness is discharged through the screen, and the coarse particles return to the crushing chamber for further crushing.

Discharging: The crushed material is discharged through the discharge port, completing the entire crushing process.

Ⅳ. Choose a high-quality cage crusher to improve production efficiency

When choosing a cage crusher, you need to consider the following factors:

Material characteristics: including the hardness, humidity, viscosity, etc. of the material.

Production requirements: Choose a suitable model according to production needs.

Equipment quality: Choose a reputable manufacturer to ensure reliable equipment quality.

After-sales service: Perfect after-sales service can ensure the normal operation of the equipment.

As a high-efficiency and energy-saving crushing equipment, cage crusher plays an important role in the field of limestone crushing. It is believed that with the continuous advancement of technology, cage crusher will be used in more fields and bring greater benefits to industrial production.