Introduction of Ring Die Pellet Machine

Ring die organic fertilizer granulator is a granulation equipment for producing compound organic fertilizer granules.

It mixes the organic matter in the raw materials with other required nutrients, and makes columnar granular fertilizer through heating, extrusion, granulation and other processes. This granulator can be used for granulation processing in many fields such as organic fertilizer, compound fertilizer, feed, etc.

Features of Ring Die Pellet Machine

The ring die pellet machine uses the ring die as the main working part, and squeezes the raw materials into pellets by rotating the ring die, which has high pelletizing efficiency and consistent particle size.

The size of the pellets can be adjusted by replacing molds with different apertures to meet different pellet requirements.

The ring die pellet machine usually has a high production capacity, can produce pellets continuously and stably, and improve production efficiency.

It is suitable for a variety of pelletized raw materials, including feed, sawdust, biomass, fertilizer, etc., and has a wide range of applications.

Energy saving and environmental protection: With energy-saving design, some equipment also has environmental protection characteristics, which meets modern environmental protection requirements.

The ring die pellet machine has a simple structure, stable operation, convenient maintenance, and high reliability.

In general, the ring die pellet machine has the characteristics of efficient production, flexible adjustment, wide application, and uniform particles. It is a commonly used pelletizing equipment and plays an important role in the pellet production process.

Working Process of Ring Die Pellet Mill

First, the raw materials are added to the feed hopper, and then compressed into a solid state under pressure in the compression chamber. Then, the compressed raw materials enter the granulation chamber for granulation, and finally form granular products after lubrication by the lubrication system and are discharged from the discharge port.

The produced fertilizer granules have a high density, are easy to transport and store, and can better extend the fertilizer effect time.

Technical Parameters of Ring Die Pellet Mill

| Model | GF-25 | GF-30 | GF-35 | GF-42 |

| Capacity (t/h) | 1-2 | 2-3 | 2-5 | 3-8 |

| Power (kw) | 30/37 | 37 | 55 | 75 |

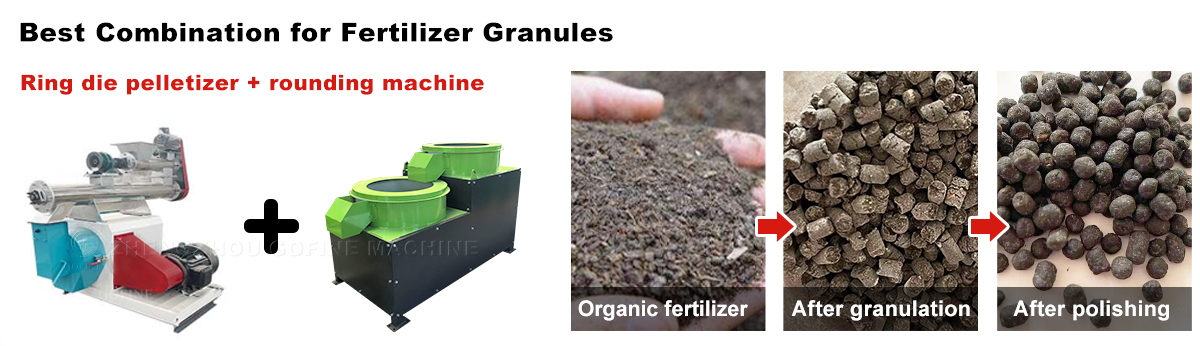

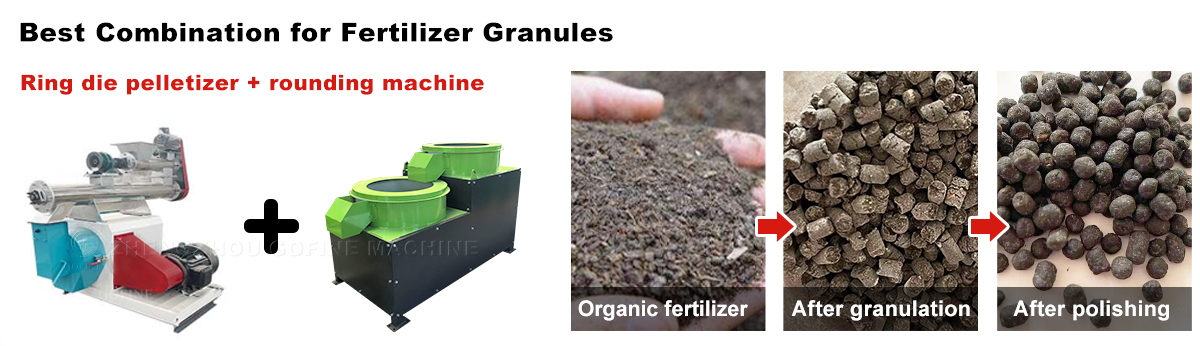

Auxiliary Equipment: Ball Type Pellet Polishing Machine

The ring die pelletizing machine combined with the rounding machine can turn the cylindrical granular fertilizer into round spherical particles.

The rounding machine is a device used to polish and shape the particles. It is used to treat the surface of the particles to make them smoother and rounder. The rounding machine rolls the particles inside the machine through rotation and friction, thereby achieving the effect of polishing and shaping. This helps to improve the appearance quality of the particles and increase the market competitiveness of the products.

The rounding machine is divided into primary, secondary and tertiary rounding, which can be purchased according to the production requirements.

More Fertilizer granulator

Want to know more about fertilizer granulation equipment, welcome to contact me!